The Importance of Using Explosion-Proof Equipment:

1. Prevent Production Interruptions and Ensure Economic Stability

Many industries exposed to explosion risks (such as petrochemicals, pharmaceuticals, and grain processing) are vital pillars of the national economy. An explosion could cause a prolonged plant shutdown, impacting product supply and market stability. Explosion-proof equipment is the cornerstone of maintaining continuous, stable, and safe production in these critical industries.

2. Comply with national laws, regulations, and standards.

Countries around the world (including China) have strict laws, regulations, and standards governing equipment and operations in hazardous locations (such as China's GB 3836 series). Using certified explosion-proof equipment is essential for businesses to operate legally, pass safety audits, and avoid legal penalties and liability.

3. Protect the environment and prevent secondary disasters.

Explosions are often accompanied by leaks of toxic and hazardous substances and fires, causing severe pollution to the surrounding air, soil, and water, resulting in long-term environmental disasters. Explosion prevention itself is an important part of environmental protection.

Product Description:

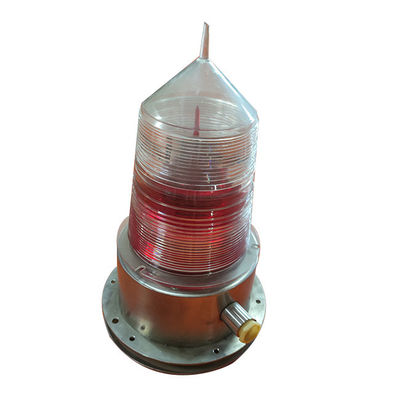

The Explosion Proof Alarm Lights, also known as Spark Proof Emergency Beacons, are designed for hazardous environments where the presence of flammable gases or vapors could pose a risk of explosion. These Ignition Protected Alarm Flashers are crucial safety devices that provide visual warning signals in emergency situations.

With a ceiling mounting configuration, these Explosion Proof Alarm Lights are easy to install in various industrial settings. Their quick emergency start time of less than 0.3 seconds ensures immediate activation when needed, alerting personnel to potential dangers swiftly and effectively.

Operating at a standby current of less than or equal to 50mA, these Ignition Protected Alarm Flashers are energy-efficient without compromising on performance. The low power consumption range of 5 to 40W allows for continuous operation without excessive energy usage, making them a cost-effective solution for industrial safety applications.

Features:

- Product Name: Explosion Proof Alarm Lights

- Mounting: Ceiling

- Item Type: Explosion Proof Obstruction Lights

- Flashing frequency: 150 Times/min

- Ip Rating: IP66

- Emergency Start Time: <0.3s

Technical Parameters:

| Color |

Red, Yellow, Blue, Green, customizable |

| Corrosion Resistant |

WF2 |

| Emergency Start Time |

<0.3s |

| Mounting |

Ceiling |

| Lifetime |

50000 Hours |

| Standby Current |

≤50mA |

| Input Voltage |

220VAC, 50Hz, 24VDC |

| Ip Rating |

IP66 |

| Power Consumption |

5~40W |

| Item Type |

Explosion Proof Obstruction Lights |

Applications:

1. Petroleum, Chemical, and Natural Gas Industries (Gas and Steam Environments)

This is the most typical and demanding application area for explosion-proof lamps. These environments are subject to large-scale leaks or volatilization of flammable and explosive chemicals.

Petroleum: Drilling platforms, offshore platforms, refineries, oil storage tank farms, oil pumping stations, and underground spaces at gas stations.

Chemical: Various production workshops, reactor areas, distillation towers, raw material and product warehouses (especially those storing solvents, alcohols, olefins, etc.), pipeline corridors, and filling areas within chemical plants.

Natural Gas: Natural gas purification plants, compressed natural gas (CNG)/liquefied natural gas (LNG) stations, gas pressure regulating stations, and gas pipeline valve shafts.

2. Mining (Primarily methane and dust environments)

Coal Mines: All areas including underground tunnels, mining faces, ventilation openings, and transfer stations. Deadly methane (gas) and coal dust are present underground in coal mines, requiring the use of mining-grade explosion-proof lamps (Ex d I Mb, etc.).

Other Mines: Metal and non-metallic mines that may contain combustible dust.

3. Dust Explosive Atmospheres (Dust Environments)

Many seemingly ordinary industrial dusts can cause violent explosions when they reach a certain concentration and encounter an ignition source.

Grain and Food Processing: Flour mills, sugar mills, milk powder factories, starch mills, feed processing plants, and grain warehouses. Flour, powdered sugar, and starch are all dusts with a high explosion risk.

Metal Processing: Aluminum-magnesium alloy grinding and polishing workshops, zinc and titanium powder production workshops. Metal dust can be extremely explosive.

Light Industry and Textiles: Wood processing plants (sawdust), paper mills (paper dust), textile mills (cotton and chemical fiber dust), and plastic product factories (plastic dust).

Chemical and Pharmaceutical: Workshops where combustible dust is generated during production, such as certain dye and pharmaceutical API workshops.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!